Rubber Compression Molding, Transfer Molding, Injection Molding

At Seahawk Manufacturing, we take pride in our advanced rubber compression, transfer, injection molding equipment and technologies. Utilizing new energy-efficient PLC controlled vacuum presses, Seahawk is able to maximize production and reduce costs. We then pass this efficiency on to you, supplying our products at a very competitive price.

Compression Molding Rubber

- Mold components from less than .5″ to over 52″

- Tooling costs are generally lower for compression molding processes than injection

- Compression molding is ideal for low to medium volume

- High density rubber materials including gum silicone

- Uses controlled closure of the press, temperature, and pressure to ensure tight tolerances

- Automated presses, secondary preparation, and tightly controlled preforms ensure cost effectiveness

- Virtually flash-free molding capabilities

Transfer Molding Rubber

- Mold components from less than .5″ to over 52″

- Tooling costs are slightly higher than compression but lower than injection

- Ideal for more complex parts and often over molded inserts that are low to medium volume

- Transfer molding is ideal for low to medium volumes

- High density rubber materials including gum silicone

- Uses transfer pot to preheat the material before it flows into the mold

- Automated presses, secondary preparation, and tightly controlled preforms ensure cost effectiveness

Injection Molding Rubber

- Mold components up to 30″

- Tooling costs are more expensive but the process allows for much lower part costs on higher volumes

- Ideal for medium to high volume

- High density rubber materials including gum silicone

- Process is more automated feeding the rubber through each cycle reducing cycle time and manual operations

- Automated operations including robotics improve cost effectiveness

Rubber Material Selection

- There are 1000’s of compounds to be selected from based on specifications

- We work only with high density rubber – not liquid silicone

- Custom formulations can be developed or stock materials are available

- Rubber is recommended based on the specific needs of the application including:

- Temperatures – extreme low and high

- Chemicals – fuels, oils, gases, alcohols, esters, etc.

- Stresses – including shear forces, compression, elongation requirements

- Fluids – blood, fluids, pharmacological, salt water, hard water

- Environmental stresses – UV, radiation, sour gases, hydrocarbons, salt water

Engineering Support

- Reverse engineering

- Consultation on improvements of design to manufacture

- Process development

- Project Management

- Mold design

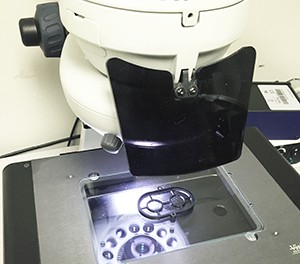

Quality Assurance

- Material Testing to conformance of specification

- First Article testing

- 100% visual inspection

- Conform to customer required quality parameters

- Visual system

- Clean room facility

Customer Service

- JIT delivery

- 24 hour order fulfillment on stock items

- Warehousing available

- Stocking arrangements such as KanBan are welcome

- Personalized Service

Secondary Operations

Cryogenic De-flashing

For precision and tight flash requirements, SeaHawk uses cryogenic de-flashing. This allows us to hold flash requirements to tighter tolerances. With this process we can hold flash tolerances to .002” thick by .010” long or better.

Cryogenic deflashing is a process that uses liquid nitrogen to create cryogenic temperatures that aid in the removal of flash remaining on parts after the molding process. These temperatures cause the flash to become stiff or brittle and to break away cleanly. Cryogenic de-flashing is the preferred process when removing excess material from custom molded parts that require tight tolerances on flash.

Specialized Packaging

- Preformed for specific shapes

- UV Shipping bags

- Per customer requirements

Sub-assembly

Contact us today to discuss your rubber compression, transfer, injection molding needs!