Your custom molded rubber solution source – whatever industry.

Seahawk Manufacturing’s molded rubber experience and expertise span nearly 30 years and a variety of industries. If your product calls for rubber components—whether you’re in the oil and gas, construction, automotive, filtration, medical, aerospace. electronic, sporting goods or any other industry—we invite you to put our skills and capabilities to work for you.

With SeaHawk’s abilities to mold virtually any type of rubber, and our experience in bonding rubber to a wide range of metals, we can create a solution that meets your specific needs and budget.

- Medical Device Rubber Components – Diaphragms, Seals, Gaskets, Valves, and Custom Shapes

- Aerospace – Molded Rubber Gaskets. Seals. and Over Molded Components, bellows

- Rail & Transportation – Vibration Dampener, bellows, plugs, Isolators, seals

- Industrial – High pressure seals, fabric reinforced diaphragms, rubber o-rings

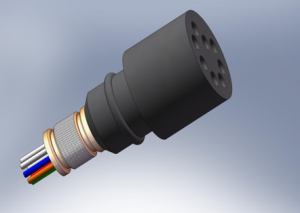

- Electronic – Rubber Parts including Interfacial Seals, EMI/RFI Shielding Components, grommets, rubber caps

- Marine – Underwater high pressure seals, environment resistant rubber components, rubber gaskets

- HVAC – Seals, Diaphragms and More Rubber Components

- Oil & Gas – Packer Elements, spring and fabric reinforced seals, reinforced diaphragms, over molded seals

Environments that demand:

- Temps from sub-cryogenic to 260 degree C

- Pressures up to 3000 PSI

- Extreme chemicals hydrocarbons, jet fuel

- Steam – repeatable autoclave

- Ozone, UV and extreme weather resistance

- Radiation resistance

- Hard water and aging resistance

- Fungal and Microbial resistance

- Noise and vibration resistance, low friction

- Tight dimensional tolerances

Whatever your industry, contact us for rubber molded parts

manufactured to your specifications – Click Here.